Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Izanami" with Nickel Magnesite gemstone handle

Jay Fisher - Fine Custom Knives |

|||

New to the website? Start Here |

"Izanami" with Nickel Magnesite gemstone handle |

||

Beyond simple tools: fine instruments and professional works of art.

What would a knifemaker make for the most important person in his life, his wife? What kind of knife would accomplish the many-faceted crossover performance of a home kitchen, and literally last the rest of the chef's life? What accessories would work best for the application?

If you're a fan of this website, and my chef's knives, you probably already know about the knife I made in 1987 that has been the workhorse in our kitchen. If you aren't, here's the link that will tell you all about it.

When I designed the Corvus, Kim let me know that it was just the right size for her hand, with a blade shape that was extremely usable, with the right size to handle without being too large, heavy, and unwieldy. I decided I would make one for her for Christmas 2020. This is her Corvus.

Sadly, Kimberley Fisher passed away from cancer in 2021. Updating this paragraph, I'm so honored to have known this wonderful human being for almost 20 years.

The name "Corvus" comes from the Latin name for the family of crows. I have a series of these on my Patterns Page, in the pages numbered in the 90s. You'll see Corvus, Corvid, and other similar knife pattern styles. I chose these names because the blades reminded me of the beak of the crow and raven; not too big, yet stout, working tools suited to a variety of uses. We raised ravens when I was a kid, and they are genius birds. They could probably untie a complex knot with their beak alone; I have nothing but respect for their skills and place in our world.

ATS-34 is a high molybdenum stainless steel, and when properly treated forms a high amount of carbides and the molybdenum encourages carbide nucleation sites that stabilize higher energy areas of the microstructure, making it a very tough steel. The resultant molybdenum carbides, chromium carbides, and multi-element complex carbides make the steel extremely wear-resistant. It also has high chromium, and when properly heat treated is corrosion-resistant enough to earn the qualification of Food Contact Safety.

Of course, I performed my best treatment, my T3 deep cryogenic process on the blade. The technical aspects of this "tertiary third" formation of carbide structure takes over a week of continuous processing, consisting of 33 individual specific steps. These are accomplished with high accuracy furnaces working at 2000°F, cryogenic equipment working at -320°F, tempering ovens accurate to 0.5°F, and numerous staged and ramped process parameters and specialized equipment. This results in the very best condition of the steel, it's tough, hard, wear-resistant, corrosion-resistant and strong.

No other knifemaker, no factory, no machine shop, and no heat treating facility will recreate the incredible condition of this blade steel that exists in these knives. Tempered to HRC 61.5, the result is extremely wear-resistant knife blade, with high toughness in the thinnest of cross-sectional geometries, a strong blade that seldom needs sharpening.

This Corvus is ground with a 12" diameter contact wheel, consequently it has an extremely thin and continuously thin blade. At the thickest, the spine is only .083" (2.1 mm). Yes, that's 83 thousandths of an inch thick at the spine! The cutting edge is about .030" thick behind the relief, and the thinnest part of the hollow grind is about .024". This, along with the stiffness of the high molybdenum steel, the treatment, and the geometry allows me to create a durable and thin scalpel-like blade.

The Corvus has a good heel, to keep the fingers off the board, and just the right curvature for board work. I designed it to have a bit of a rounded point that wasn't too tiny and thin for strength, yet with a good geometry for getting into tight trimming and piercing. Of course, it's completely mirror polished for easy cleaning and the highest corrosion resistance.

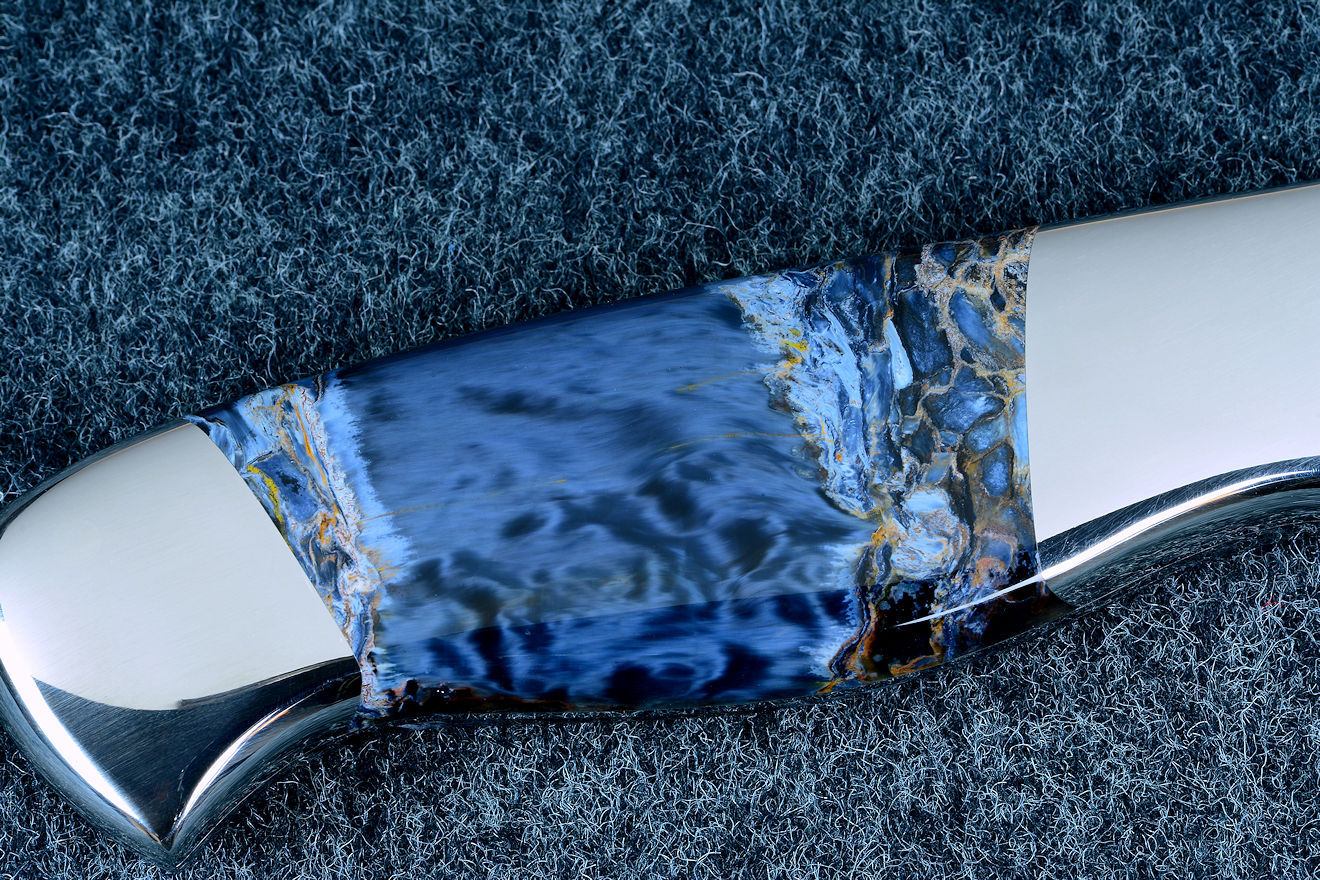

In the photo above you can see the incredibly thin spine. Remember, this is only .083" (2.1 mm) thick at the thickest. You might also notice that the knife has a fully tapered tang, which is almost unheard of on this thin of a knife. This is done for weight balance and aesthetics, and it's difficult to do right, and still have a seamless fit. If the spine is .083", how thin is the tang at the butt? It's .035" (0.8 mm) and yet supports the handle well. The bolsters are mounted with zero-clearance peened pins of 304 stainless steel, and dovetailed to lock the gemstone handle scales to the tang. You might have noticed that the gemstone scales are also bookmatched.

One of the most striking things about my wife's Corvus is the gemstone handle. This is Pietersite, from Kuriman, Namibia, Africa. You will be hard-pressed to find any of this large enough for knife handles now, the mine played out in the late 1990s, and it's becoming more scarce every year. There is also a Pietersite that comes from China, but it doesn't have the rich blues and patterns; it's almost a different stone entirely, with more reds and yellows. Here's a link to a knife with Chinese Pietersite on the handle.

Pietersite is a silicified crocidolite in quartz, similar to a brecciated tiger's eye. However, the description does not do it justice. For example, this is a very hard agate. Tiger eye isn't near as hard and tough; Pietersite is a true agate, with transparent areas and depth and cryptocrystalline nature that is surprising to work with. This Namibian Pietersite is much harder than the Chinese version, and very durable and solid, despite the appearance of lines and different colors and patterns.

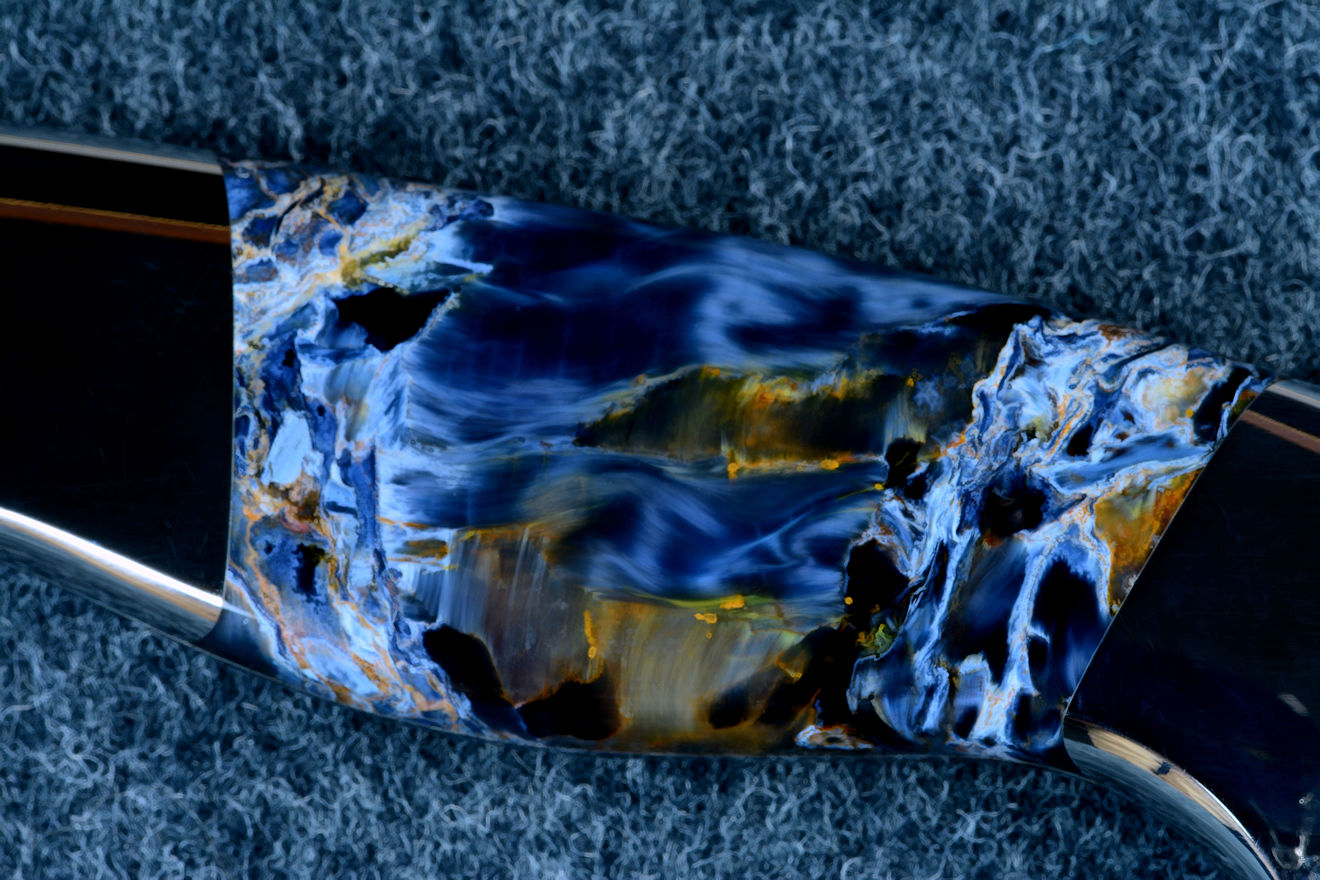

Technically what you are admiring (and I know you are) is the "chaotic chatoyancy" of this gem. It comes from a patchwork of bundles of angular fragments of the amphibole riebeckite. There are some great studies out on this amazing stone available on the internet, and I'll admit it's one of my most "asked for" stones for knife handles. From the photos, it's easy to see why. Unfortunately, it's rare and expensive, and isn't readily available, so my projects with Pietersite are few.

The photos above were taken with a white reflector card above the knife. This is why the bolsters are white. This imparts some glare on the stone surface, since it's polished like glass. You can make out the edge of the reflective card in the bottom fourth of the handle; it looks like a horizontal line where the stone appears different, and the bolsters are not white. In the next photo, I've removed the white reflector to let the light play around in the stone and come back out naturally (without the reflective glare).

Imagine what this stone looks like in the full sunlight. You can't. It's beyond description, and far beyond the limitations of the photographic and digital medium that your are seeing now. As the stone is tilted and turned in the light, the dancing chatoyant (cat's eye) effect is sublime.

Here's another photo magnification without the reflector. Remember, you are looking into the glassine surface of the stone, like a deep blue turbulent sea.

When we had chef Tommy Badger Brown and his crew (Ken Korpi, Matt Levinson, and Todd Westphal) visiting early in the spring of 2020, we discussed chef's knives and all of the uses, accessories, and necessities of the typical chef's knife. I use the singular word "knife" because a chef can only use one knife at a time. As the chef uses the knife, he (or she) picks it up, and puts it down many times during the preparation. Most people will just lay it on the counter or on the cutting board. They wouldn't put it in a block or holder, because it has not been washed. The knife can move, spin around, and present a razor-scalpel edge to the chef's hand, since it doesn't have a secure place to rest.

This issue is one of the reasons I first created the microfiber towel set that I include with my chef's knives. The towel gives a resting place for the knife, while in use, and another place for it to dry. Read more about the issue and the microfiber towels at this link on my Chef's Knives Page.

Another issue is where to store the knife, particularly if the knife is singular and doesn't have a block or stand. Sometimes, the knife might need to be put in a drawer, and this would be dangerous to the hand reaching in, and brutal to its cutting edge and other stainless utensils. The fine knife is razor-scalpel sharp and needs to be respected. A dedicated slot in a drawer is precious and limited real estate in most kitchens.

This is how my wife and I came up with the idea for the "prise," (pronounced preeze or prize)The name comes from the French prise de fer, which is a movement used in fencing in which a fencer takes the opponent's blade into a line and holds it there in preparation to attack. The French word prise simply means taken.

The prise is a home for the knife, it is a rest for the knife, it is more than that, it is a trap for the knife that holds it "in a line" in preparation for the next "attack" of cutting and board work.

You might be tempted to call the prise a rest, like a spoon rest, merely a place to plop down a dirty utensil. It is so, so much more. A spoon or utensil rest is a temporary fixture, remaining empty most of the time, and it can slide around. It is often in the way, and can be difficult to clean. A spoon rest is not specifically designed for an individual utensil, and it typically only elevates the dirty part from the countertop. A spoon rest is no place to store the utensil, it's not safe, it's not permanent, it's not long-lasting. It rarely fits the utensil, since it is not designed around the utensil.

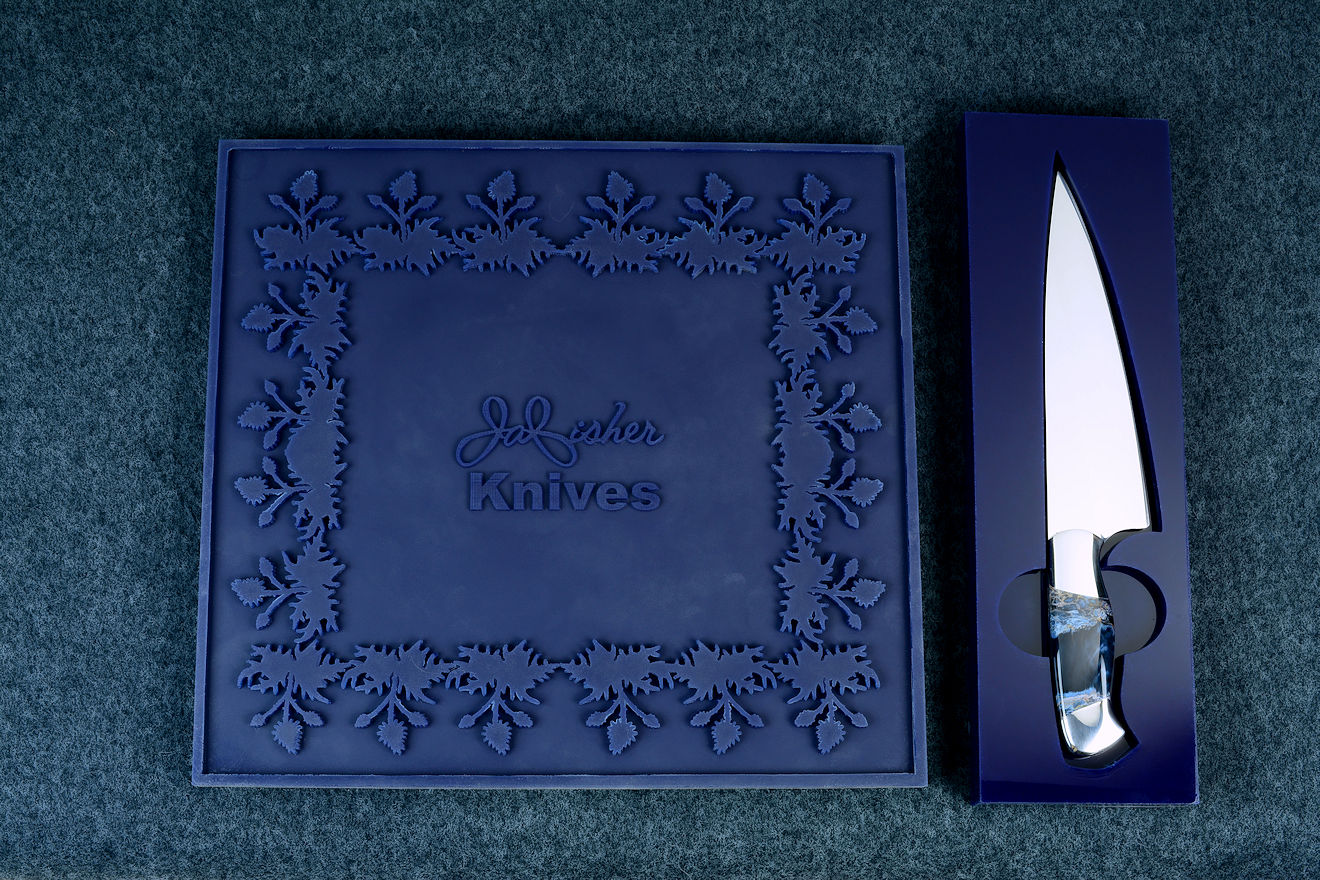

The prise is so much more. I made the prise in food contact safe high density silicone rubber, and dyed it to match the ensemble. This is high strength material, with a 600 psi tensile strength. It's resistant to 450°F (204°C) heat, and no food stuff sticks to it. It's flexible, yet stout and thick, and can be easily cleaned, rinsed, and even baked dry. This is a wonderful material, and I created the mold and hand-cast the prise so that the silicone fits the specific knife. I've designed it with finger holes for easy removal, and the bottom has a base that is a rough texture that grips any countertop it sits on.

Gripping is important! The silicone prise is "grippy." Being of smooth silicone, nothing slides around on it. If the chef is working with his knife, and needs to set it down for a period, he doesn't need to worry about placing the knife precisely in the socket of the prise, just dropping the knife on the prise assures it will not move; it wont' even budge! The knife can sit atop the prise and still be sound and secure.

Even so, the silicone will not grip moisture, foodstuffs, or anything else, and usually a quick rinse is all that is required to clean it. Like any knife, board, or utensil, a brush cleaning with soapy water is advisable when working with raw chicken and meats, but that's easy enough. You can even plop it in the dishwasher, but I don't think you would ever need to. The silicone prise dries almost instantly; water just beads up and flows off of it.

Storage issues are eliminated with the prise. since it's color-matched to the knife and ensemble (I dyed this one in a deep cobalt blue to compliment the Pietersite gemstone handle), it looks great on the counter. When the knife is not being used, it's nested down in the prise, and the cutting edge and point of the blade can't be touched. It won't fall out, it won't move, it's safe, and yet immediately available. The tough silicon will resist cutting, because it flexes away from the edge, and because of the grippiness, the prise will not slide or move on the counter; it clings to the counter. If there is a need to store the knife in a drawer, the prise is a dedicated, rectangular safe nested receptacle for the knife, assuring it does not move, and does not contact any other utensil.

The prise is dense. This means solid, and with some weight, so it's durable and won't move around. This prise comes in at almost two pounds; it's an inch thick and over a foot long (specs below). This is why you won't see a prise offered anywhere else, it's a massive, solid piece. Yet, because of its size and softness, it's easy to manipulate and clean.

It's a perfect holder/rest/trap/storage device, and it's completely food contact safe. I'm certain I'll be making more of these, and I've cast my maker's mark into them with pride.

You might have noticed that the prise is designed to have the reverse side of the knife facing upwards. I did this because my chef is right-handed. When the prise is stored beside the board, the point is away from her and the cutting edge is also away from the chef's hand. If the prise is placed along the top edge of the board, the cutting edge is away from the right-handed person when they pick up the knife, the safest arrangement. Of course, I can make these for a left-handed person as well; the orientation will be reversed.

What about the board? I thought a board to match would be a good idea, and here's my take on it: Many boards are large and unwieldy. They are thick and heavy, with heavy handles, heavy feet to elevate them, or they are plastic and slide around on the countertop. This may be fine for some of us guys with large, strong hands, but it can be difficult to move a board to wash it.

I designed this one for my wife with intention of ease. I made the board from a solid piece of Jatoba which is also called Brazilian Cherry. It's a stout, strong, dense wood, resistant to decay, with a close cellular structure, and is found on some of the best cutting boards made. I didn't make it overly large, it's about 12" x 13". I cove-cut both sides so the edge is thin and easy to grab and lift, as well as easy to clean. I didn't put a liquid groove it, but could if needed. The board is simply a fine, thin and stout cutting board, easy to lift, clean and flip. It's treated with food safe sealant, mainly beeswax and carnauba wax.

It's the holder or base where the magic comes. Since I got into the hand-casting of the prise, I followed this same idea with the board base. It's cast in even higher strength silicone rubber, an 800 psi tensile strength food contact safe silicone. I died it to match the prise and handle and ensemble. It looks a little lighter in the photo because I didn't create a smooth mold; I created a somewhat roughened surface of the mold, so the board would have the right amount of grip. The bottom of the board prise is smooth and grippy, the top has a nice texture of my maker's mark and leafy thistles to elevate and secure the board, offering some ventilation.

The idea is that a board should not slip or move. What better way then to create a thick, strong silicone pad to stop this? You might think that these are available from other vendors, but that would be a weak substitution. This base is heavy, grippy, strong, thick, and solid, and the board absolutely will not move around, it won't budge on any counter. In fact, the slicker and smoother the countertop, the more it grips! It has enough weight to stay put, and that's the idea, after all, that the knife moves and the board shouldn't.

I've also sized it exactly to the board. It can trap any liquid draining off the board, and being a big piece of soft silicone, is easily rinsed. The board is elevated while on the base, being held up by the floral designs in the casting. You could say that the silicone base is a prise for the board!

One more thing: the silicone rubber prise for the board is a high temperature food contact safe material. This means that it can double as a pot rest or cooling pad, and may have many other applications. You could even bake on it! I designed it with a lip around it to retain fluids, yet it flexes easily. You might think that it would be difficult to clean with all those thistle leaves, but remember, this is silicone, and nothing sticks to it!

The photo above shows the most typical orientation for the set. The board is accessible, and solid and secure in its own heavy silicone prise, and the knife is above, secured in it's silicone prise, with the cutting edge away from the chef, and the handle ready for the right hand. Easy reach, simple arrangement, and a happy chef!

A knife for the most deserving and warm heart I know, the woman I love, my wife!

I miss her so.