Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Izanami" with Nickel Magnesite gemstone handle

Jay Fisher - Fine Custom Knives |

|||

New to the website? Start Here |

"Izanami" with Nickel Magnesite gemstone handle |

||

Beyond simple tools: fine instruments and professional works of art.

A classic pair of knives is a traditional chef's knife based on the French Sabatier design, paired with a small to medium-sized knife with a more slender tip profile. In this chef's pair, I've made my popular Concordia chef's knife with my Talitha utility knife. I've used the finest premium materials, with sculptural stands that incorporate color, design, shape, and rhythm to the entire piece. This is one of the very finest chef's pair of knives you will ever see, truly one of the very best ever made.

CPM154CM is a powder metal technology stainless steel, made by Crucible Industries here in the United States. This is an extremely fine steel, a high alloy stainless steel that is made with powder metal technology. This means the steel is first a finely and thoroughly mixed powder of very specific alloy content, and it's sprayed and fused into a billet. This creates an unsegregated mass, and in layman's terms means that the alloy components are completely and evenly distributed throughout the steel. This allows an overall high content of alloy elements, and their even distribution means the steel has little to no visible grain structure. This also results in a very uniform microstructure throughout, after proper treatment. This is, then, a high alloy, chromium-molybdenum, hypereutectoid powder metal stainless tool steel.

This stainless steel is high in molybdenum, which is a strong carbide former, and its amount creates carbide nucleation sites that stabilize higher energy areas of the microstructure, making a tougher steel because of fewer dislocations and irregularities. It also has high chromium, and when properly heat treated is corrosion resistant enough to earn the qualification of Food Contact Safety.

Just choosing the advanced steel type for the knife is not enough. To bring out the very best in tool and knife blade performance, a substantially complicated heat treating (hardening and tempering) regime must be accomplished. To do this, I perform a proprietary heat treating process I call "T3." The technical aspects of this "tertiary third" formation of carbide structure is not a simple process. It takes over a week of continuous processing, consisting of 33 individual specific steps. These are accomplished with high accuracy furnaces working at 2200°F, cryogenic equipment working at -320°F, tempering ovens accurate to 0.5°F, and numerous staged and ramped process parameters and specialized equipment. One small mistake will yield a less than optimum blade, and I'm determined to create the very finest knives made in the world today.

Consequently, no other knifemaker, no factory, no machine shop, and no heat treating facility will recreate the incredible condition of this blade steel that exists in these knives. Tempered to HRC 60, the result is extremely wear-resistant knife blades, with high toughness in the thinnest of cross-sectional geometries, a blade that seldom needs sharpening. These knives will literally last for generations.

My Concordia design is very popular, and typically I make these with a hollow ground blade. Hollow grinding has the advantage of a very thin cutting edge, high stiffness through a thicker spine, and has a very robust geometry. In this Concordia, I wanted to create a chef's knife that was incredibly lightweight for its size. This is no easy task, since the Concordia knife blade is 9" long and 2" wide. I accomplished an accurate, even, and graduated flat grind. This grind is so well executed that the knife is a literal mirror. No hand-sanded finishes here, no rough or toothy surface to resist cleaning: this is a mirror-smooth flat blade that is, literally, a mirror!

The taper of the blade grind is profound. Just behind the cutting edge is the thinnest area, and it's only 0.0135" thick. That's thirteen thousandths of an inch thick, less than the thickness of four sheets of standard paper. This is why I used this particular steel, because it can be made very tough and fracture-resistant in thin sections. The blade thickens in cross section, in an even taper toward the spine which is only 0.127" thick. The spine is also tapered to the point. What this means is that the entire grind taper of the knife blade is less than 4°!

For the chef that requires a tough, lightweight, and extremely fine-edged large knife, the Concordia is supreme. It has a substantial heel, with a curve at the cutting edge that is just right for the board. It has a very acute, thin point, with limited lateral flexing at the tip, a prize of a knife for the skilled and accomplished chef. And, of course, it's as sharp as a scalpel, with a single bevel cutting edge.

The Talitha makes a perfect companion for the Concordia. The blade shape is a slight trailing point (the point trails higher than the spine) which creates a fine, narrow point with the added strength and stiffness of a traditional hollow grind. This grind profile means the spine is very strong, and there is no flexing at the tip. This is actually a stiffer knife than the larger Concordia. The tight, acute curve of the blade means this is a knife that can be used in a wide array of cutting chores, a true crossover design, accommodating paring and boning, trimming and separating with comfort.

Each knife has a unique handle shape. The Concordia has a long handle with a good section of belly for a secure and full grip. It has a light hawk's bill at the rear bolster to lock it into the hand for security, and the weight of the handle balances the knife in a traditional grip. The front bolster of the Concordia is minimalized with a concave polished face to help keep the blade weight reduced, in line with the overall knife design. For lighter use, a pinch grip along the thin spine with three fingers of the hand in front of the handle belly are comfortable.

The Talitha has a palm-style grip, a narrow neck at the front bolster with a continual curve at the spine and inside the tang toward the wide rear bolster. The butt area of the handle nests in the palm of the hand in a standard grip, giving the hand complete coverage of the handle for a great deal of control. The handle shape also accommodates reverse grip, finger on spine for accurate and decorative cuts, and enough control for paring.

The bolsters of both of the knives are made of 304 high nickel, high chromium austenitic stainless steel. This is the same steel used in Food Contact Safe and approved restaurant equipment, a steel tough enough to be used for stainless steel nuts, bolts, and fasteners. This is a high chromium steel that requires no care whatever; it's extremely corrosion-resistant and will not darken or oxidize in any way, ever. I've mounted the bolsters with zero-clearance peened pins; they are permanently bonded to the knife tangs. The bonding is actually stronger than spot welds since the pins penetrate completely through the tang and are swelled in place. The bolsters are sealed with Food Contact Safe sealant, so the knives meet all Food Contact Safety requirements. The bolsters are rounded, contoured, and polished for comfort, and are dovetailed to lock and bed the handle scales to the fully tapered tangs. I chose to offer a very clean, smooth spine with no filework for the easiest cleaning possible.

The natural handle material is stunning; it's hard, it's tough, and incredibly durable. This is Deschutes Jasper gemstone, coming from the Deschutes River area near Biggs Junction, Oregon. While the area is known for Biggs Jasper, the premium material found there is Deschutes Jasper. This is a finer, harder, and more even and compact form of the typical Biggs Jasper and it's richer in color and pattern. The scalloped shapes and curvy lines are interspersed with dendritic dark forms and is reminiscent of deserts and hillscapes. Jasper is a fine-grained cryptocrystalline quartz, very hard and durable, and the gemstone will literally outlast the blades. Think of the very oldest remains of man's tools; they are all hard, tough stones and rocks. This is why I call gemstone the eternal natural material.

Man cannot recreate the striking beauty, originality, and unique nature of Jasper. The process takes many millions of years and the coloring comes from impurities in the quartz structure. Jaspers have a higher degree of impurities than agates or chalcedonies, and this is why they are opaque and intensely colorful. Jasper has been adored and used by man for millennia and is mentioned in both the Old and New Testaments of the Bible. This classic material was even identified as the material envisioned for the walls of New Jerusalem.

This everlasting beauty and durability is why I also chose it also for the accent components of the Concordia and Talitha stand.

The patterned and hand-carved inlaid gemstones in the stand represent a tremendous amount of work. This is why you will find no knife stand anywhere, made by anyone in the world like what you see here. Focusing on just one inlay in the photo above, I created large domed, finished and polished carvings of gemstone, carefully fitted and mounted in hand-carved American Black Cherry hardwood. These gemstones are polished and match the handles beautifully, bringing the piece together just as I envisioned.

There are two main stand forms, each made of American Black Cherry, frequently simply called Cherry hardwood. This is a very fine American wood from our eastern hardwood forests. Black Cherry is not black in color; the name refers to the tree. You can see the natural color of the hardwood in this stand. The hand-carved and hand-finished forms are shaped in the idea of a splash, or paisley, or dolphin form that is one of the oldest decorative forms in human history. Some even see musical notes in the shape of the form. Each carved sculpture is made of several components of Cherry, with snug slots for the blade points and cutting edges. This allows the knives to be displayed completely while offering no cutting edges to the fingers for safety.

The Granite I chose is Delicatus Gold Granite from Brazil. While this granite is available in many different tones and color depths, I chose complimentary color and patterned pieces, cut, shaped, carved, ground, and polished them to fit the stand and blend well with the Jasper and Cherry components. You can see the colors almost bleed from one piece to the next, even though the materials are strikingly different. This is a hard, tough granite, an everlasting stone. The bold patterns are echoed in the substantial carved polished granite inlays.

In the photo above, you can experience the beauty and arrangement of the sculpted stand without the knives. No other person in the world, no source anywhere is as dedicated to the full concept of the knife arrangement and completion. I hand cut, carved, and polished all of the stone to a bright glassy finish, and rounded and polished the edges of the solid Delicatus Gold Granite base. The Black Cherry hardwood forms are mounted with stainless steel screws through the granite, and the base block has inlaid neoprene feet to protect any surface the stand rests upon, while allowing air to circulate underneath for sanitation and cleanliness. This is a massive block and stand, making the entire piece extremely stable and safe.

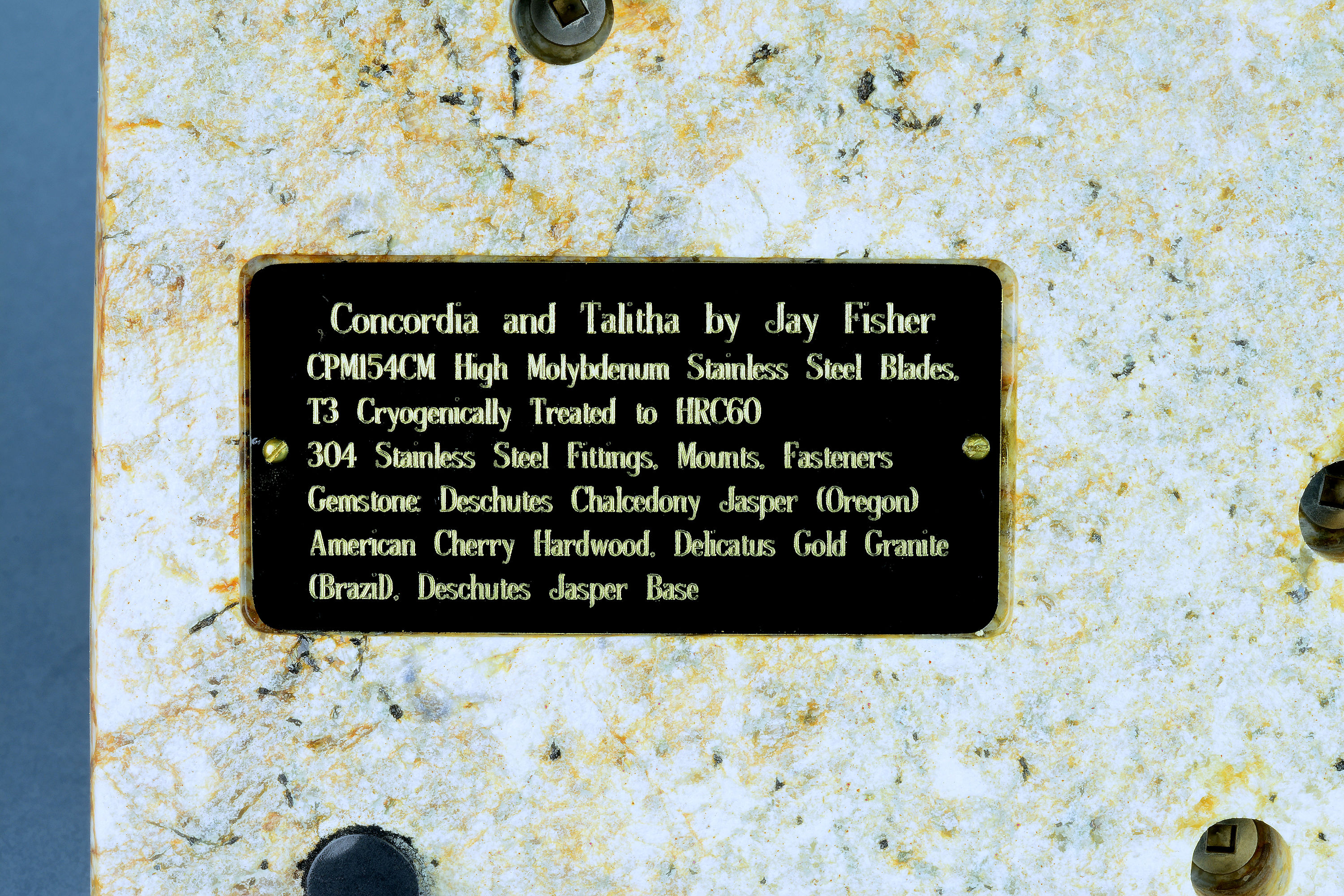

The photo above shows the bottom of the Delicatus Gold Granite base, with the inset neoprene feet, the screw mounting holes, and the legend plate. I cut a special inset for the legend plate to protect it; I made it in engraved black lacquered brass, permanently sealed and mounted into the base for posterity. Even if the documentation is lost, the provenance remains with the artwork.

This is a magnificent classic work of art in knives; a useful, working set of tools made to the pinnacle of premium materials, condition, and execution.